660

shares

With the gradual expansion of the application market of lithium batteries, the threat to the environment caused by waste lithium batteries is also growing. How to recycle and manage waste lithium batteries has also received widespread attention. However, compared with the variety of lithium batteries, the available disposal methods for waste lithium batteries are very limited.

"At present, all kinds of disposal methods of waste lithium batteries have their own problems, and the way of dismantling batteries and extracting precious metals is still the best way to balance environmental protection and economic benefits." Zhang Yongxiang, general manager of Shenzhen Taili Waste Lithium Battery Recycling Technology Co., Ltd., said.

In lithium batteries, materials containing cobalt, nickel and other elements have higher value content. Especially for nickel materials, the price of nickel in the international market has risen by more than 60% since Indonesia imposed a ban on the export of nickel ore on January 12 this year. In addition, the current technology of dismantling cobalt and nickel wastes is relatively mature. Therefore, dismantling cobalt and nickel wastes has become the main way to dispose of waste lithium batteries.

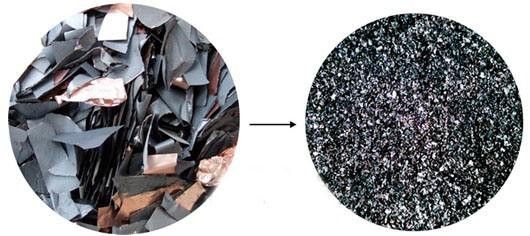

The methods of dismantling cobalt and nickel wastes include "dry process", "wet process" and "dry-wet combination". Zhang Yongxiang introduced that "dry process" mainly adopts the way of combustion, which consumes more energy and is not advocated by the state, while "wet process" metallurgical process will cause water pollution and bring new environmental protection problems. Therefore, enterprises mainly adopt the way of "dry-wet combination" to dismantle batteries.

However, due to various limitations, it is difficult to get a real commercial promotion whether it is the disassembly of lithium carbonate or the direct recovery of positive and negative materials.

Due to the serious shortage of lithium resources in the future, the recovery of lithium salts from waste lithium batteries has become a focus of attention of some professionals. Authoritative agencies predict that by 2050, the global demand for lithium metal will reach 40 million tons. At present, the global demand for lithium metal resources is up to 30 million tons. The conversion of proven exploitable lithium resources into lithium metal is only 15 million tons. There is a huge gap between supply and demand.

In this lithium crisis, China is facing a particularly grim situation. According to statistics, China's lithium reserves only account for the world's reserves. More seriously, 70% of the world's lithium resources are in the form of Salt Lake brine, while the lithium extraction technology in China is still limited to the extraction of lithium from ores, and the key technology of lithium extraction from brine has not yet been overcome. If the technology of lithium extraction from brine can not break through, the lithium power industry in China is undoubtedly in a more passive situation.

Although recovering lithium carbonate can cope with the shortage of lithium resources in the future to some extent, the high cost of recovering lithium carbonate from waste lithium batteries makes battery recycling enterprises hesitate. According to foreign media reports, the cost of recovering lithium carbonate from lithium batteries is five times the lowest production cost of lithium carbonate at present. At present, there is no breakthrough progress in this field at home and abroad.

"Almost all battery recycling has abandoned the idea of reclaiming lithium carbonate from spent lithium batteries because it is too inexpensive." Zhang Yongxiang said, "And reclaiming lithium carbonate may cause harm to the health of employees, and the project in this regard may not even pass the government's safety review."

However, the method of recovering more valuable intermediate materials, such as cathode material, negative material, electrolyte and diaphragm, directly from waste lithium batteries is confronted with the problem of unsatisfactory consistency of waste lithium batteries. It is understood that the intermediate recovered from waste lithium batteries requires high consistency. The recycled materials must come from the same kind of lithium batteries. At least the positive and negative materials and electrolyte used in lithium batteries are the same, so that they can be reused in new batteries.

The reality is that the current lithium industry in China lacks standards, and there are many kinds of lithium batteries. The components of lithium batteries are often different. Even for the same ternary material, the proportion of its own components varies greatly. It is still very difficult to recycle intermediate products in commercial applications.

660

shares

contact us

GUANGZHOU GEILIENERGY ELECTRONIC CO., LTD.

We provide customers with quality products and provide high-quality services

If you would like to leave us a comment please go to contact us